Printable Tdc Degree Wheel Add the two numbers and divide by two which in this case will be 26 22 48 2 24 degrees Move the degree wheel to read 24 degrees against the stop and then rotate the engine back to the

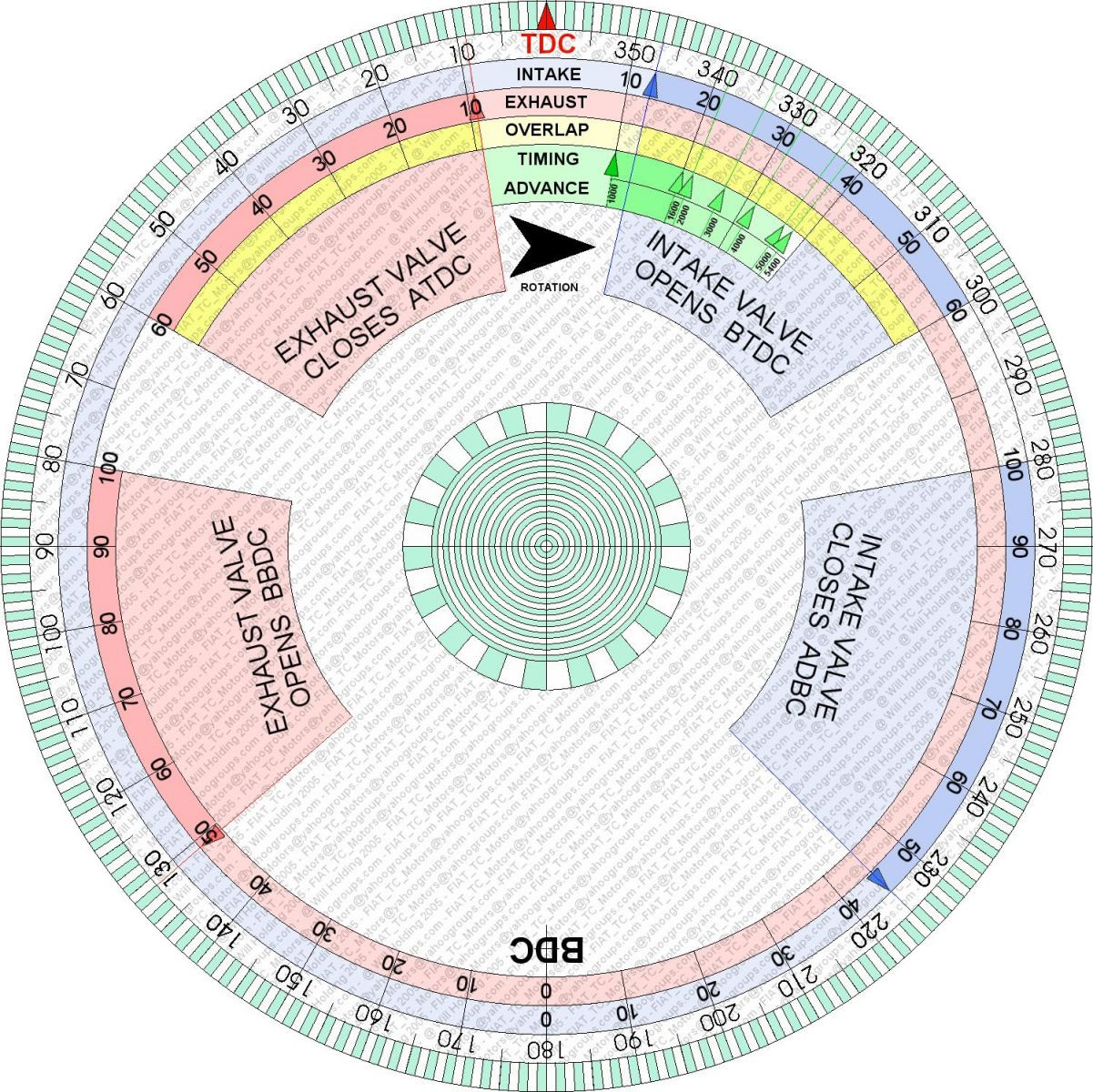

Most degree wheels are configured to display as 0 180 0 like this Moroso Pro wheel All four valve events intake and exhaust opening and closing are also displayed along with a range for intake Step1 The camshaft and timing tensioner have been installed Make sure the timing marks on both the flywheel and cam gear are aligned as per the workshop manual Step 2 For example we have our cam and it suggests we install the cam on 105 degree exhaust centrelines Adjust the tappets to the clearances recommended by the cam manufacturer

Printable Tdc Degree Wheel

Printable Tdc Degree Wheel

Printable Tdc Degree Wheel

https://i.pinimg.com/originals/d0/83/0d/d0830d82dfd9bc02fe5b7059df467f5c.jpg

The tool consists of a circular degree wheel with markings at regular intervals and a pointer that can be positioned over the markings The degree wheel is attached to the front of the engine crankshaft and the pointer is positioned at

Pre-crafted templates use a time-saving solution for developing a diverse series of documents and files. These pre-designed formats and layouts can be made use of for numerous personal and expert tasks, consisting of resumes, invitations, flyers, newsletters, reports, discussions, and more, simplifying the material development process.

Printable Tdc Degree Wheel

Printable Degree Wheel Printable Word Searches

Ennovardesign Degree Wheel Printable

Cam Degree Wheel Printable

How To Find True TDC Using A Degree Wheel And Piston Stop

Finding TDC For All Cylinders

360 Degree Wheel Printable Astrology Planets Learn Astrology Tarot

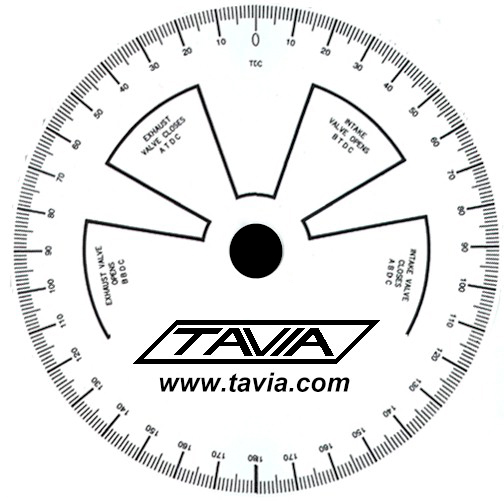

http://www.tavia.com/free_degree_wheel.html

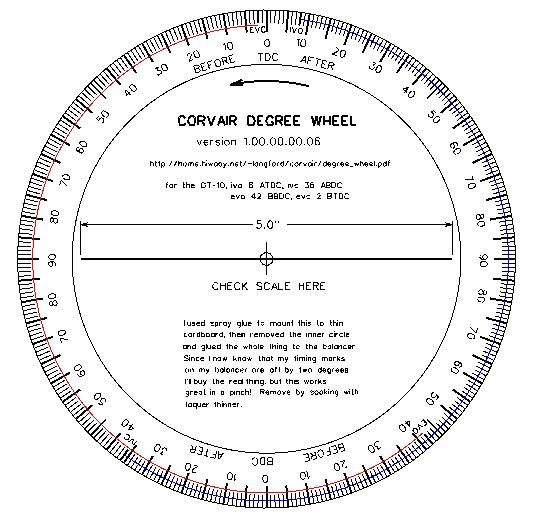

This is a full 7 diameter degree wheel The higher you set the dpi resolution on your printer the better your degree wheel will print out Paste or tape the printed sheet onto a piece of stiff cardboard and you have the best free downloadable degree wheel

https://www.motortrend.com/how-to/how-to-find-true-top-dead-center

Find true top dead center TDC on a fully assembled engine using a degree wheel that bolts to the harmonic damper and a TDC stop that screws into the spark plug hole If you haven t yet bolted

https://lambdageeks.com/camshaft-degree-wheel

A camshaft degree wheel printable typically includes markings for TDC Top Dead Center timing marks and degrees of rotation By aligning the degree wheel with the crankshaft and using a piston stop to find TDC you can accurately measure the camshaft s position and adjust it as needed

https://www.youtube.com/watch?v=q4X03-J7SUQ

Information about degree wheels What their purpose is choosing a degree wheel and how to setup a degree wheel on true top dead center TDC using a piston

https://enginebasics.com/Engine Basics Root Folder/Camshaft Timing.html

Most degree wheels allow you to measure in degrees from TDC the zero mark in both directions Count the degrees from TDC to your pointer along the shortest path In other words your reading should be less than 180 degrees

2 Procedure Attach degree wheel to crankshaft and install pointer Adjust pointer to approximate TDC on the wheel with piston at top of cylinder Install indicator to contact the piston near the center to minimize the effect of piston rock at TDC Rotate crank through TDC in normal direction and 0 indicator at the highest reading 1 Position front cylinder at TDC 2 Clamp degree wheel on sprocket shaft so pointer lines up with with 45 ATC mark 3 Rotate flywheel assembly with degree wheel clamped in place so pointer lines up with Top Center 0 mark Rear cylinder is now positioned at TDC Ignition Timing Flywheel Marks Ignition usually occurs before piston is

Now in this instances we want to be reading the white markings on our degree wheel because we are looking at our degrees before top dead centre we have our TDC marker over here 04 22 So we can see that we are at 16 5 degrees before top dead centre 04 28 Remembering that our actual specification on our cam card was 19 degrees 04 34