2 Stroke Dirt Bike Motorcycle Ignition Time Degree Wheel Printable In this video Charles show how to set ignition timing on a 2 stroke dirt bike using the three most common ignition system setups found on todays off road motorcycles Shop Now 2 Stroke

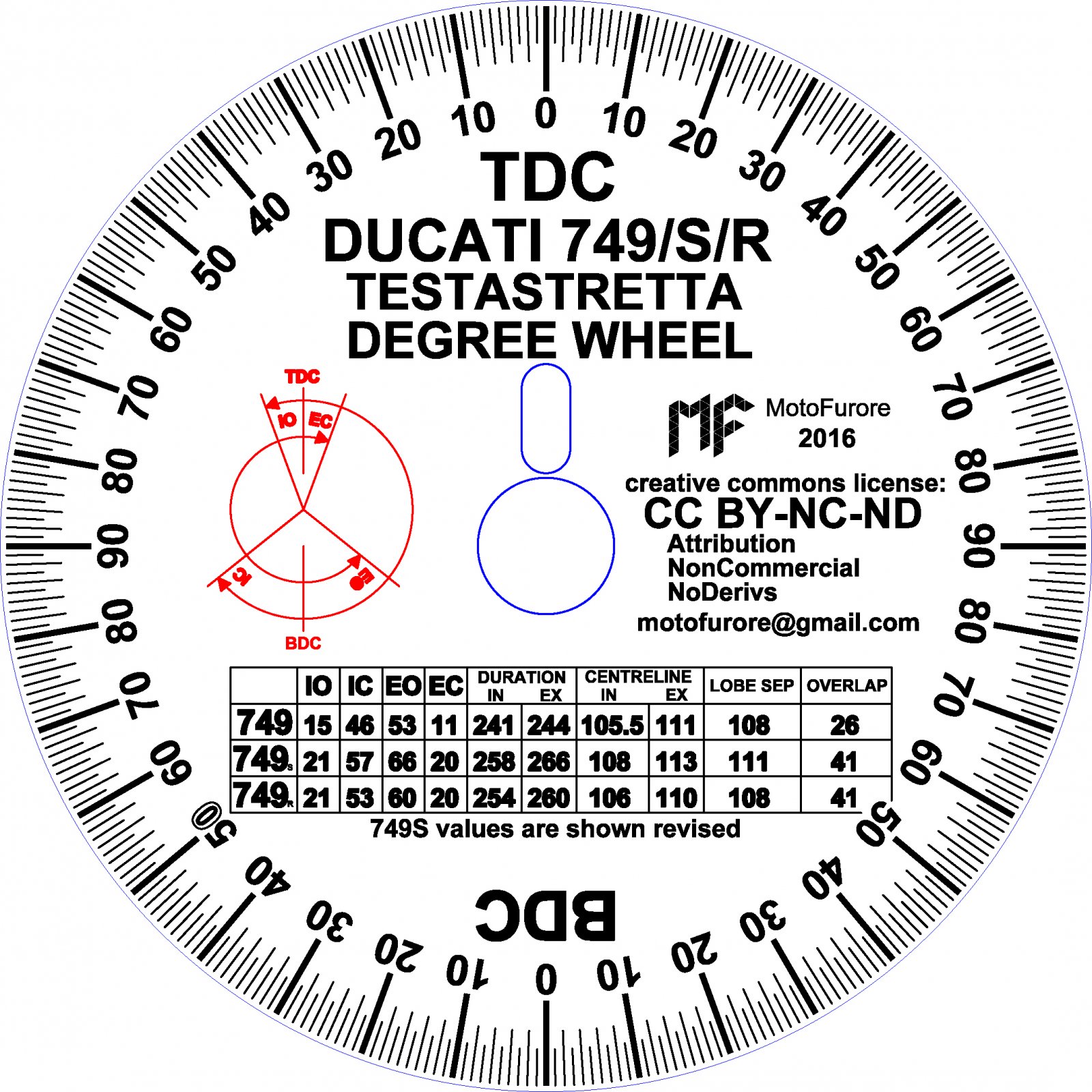

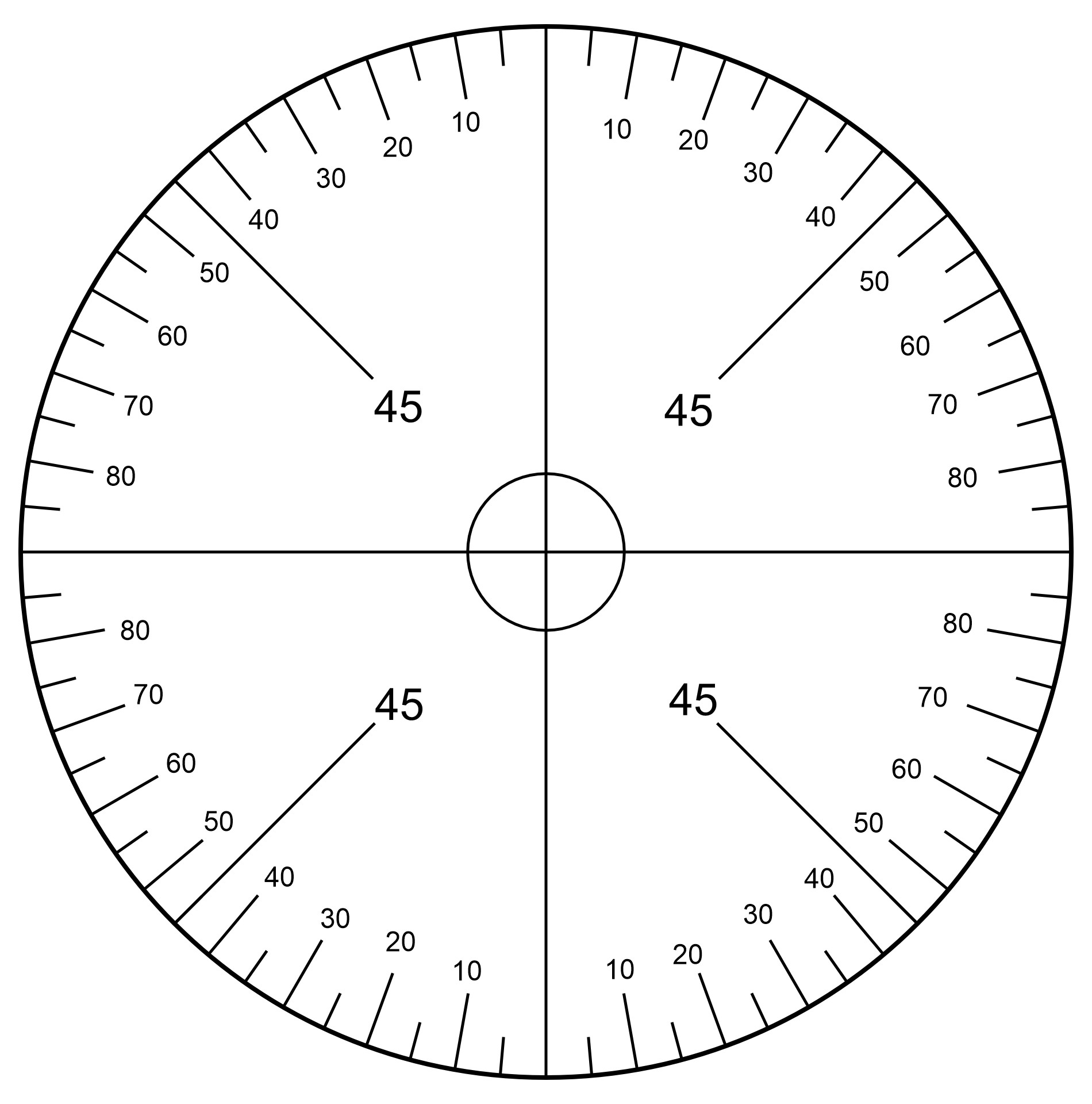

Having the ignition timing set up and adjusted properly is an often overlooked maintenance procedure that ensures your 2 stroke dirt bike engine stays operating at peak performance In this video Charles show how to set ignition timing on a 2 stroke dirt bike using the three most common ignition system setups found on todays 1 Add the measured opening and closing timings together 2 Add 180 degrees to the sum 3 Divide the answer by 2 4 Subtract the smaller value of the two opening and closing numbers from the answer to reach the lobe center value

2 Stroke Dirt Bike Motorcycle Ignition Time Degree Wheel Printable

2 Stroke Dirt Bike Motorcycle Ignition Time Degree Wheel Printable

2 Stroke Dirt Bike Motorcycle Ignition Time Degree Wheel Printable

https://www.printabletemplates.download/wp-content/uploads/4r8vpR/ducati-timing-degree-wheel-pdf-template.jpg

The process of building two strokes to race engine quality is explained in depth in this thoroughly illustrated handbook Containing over 300 full color pictures 280 pages of step by step instruction and detailed technical knowledge that can be applied to any make and model The Two Stroke Dirt Bike Engine Building Handbook is a trusted

Pre-crafted templates offer a time-saving solution for creating a varied range of files and files. These pre-designed formats and designs can be utilized for different personal and expert jobs, consisting of resumes, invites, flyers, newsletters, reports, discussions, and more, improving the content production process.

2 Stroke Dirt Bike Motorcycle Ignition Time Degree Wheel Printable

16 Useful Printable Protractors Kittybabylovecom Printable Circle

Printable Degree Wheel Grumpys Performance Garage

Printable Wheel Printable Word Searches

Degree Wheel Printable Printable World Holiday

Motorcycle Parts Other Motorcycle Engines Parts Late 1969 Later

10 Best 360 Degree Wheel Printable Printablee Free Printable

https://www.liveabout.com/2-stroke-ignition-timing-3971…

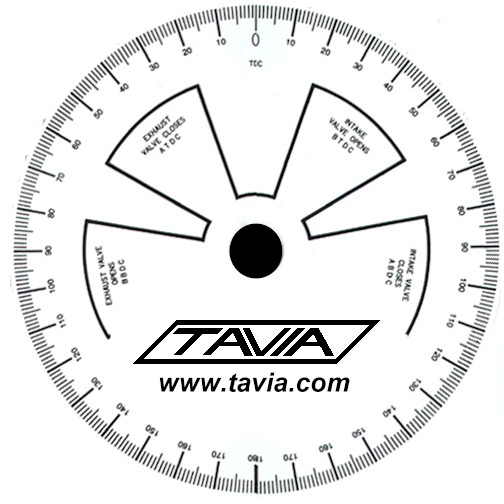

Setting 2 stroke ignition timing is fairly simple The majority of classic 2 strokes have ignition systems that fall into one of two types contact points inside a flywheel magneto Villiers and early Japanese engines and external contact points mounted on an adjustable plate with an internal flywheel

https://dirtrider.net/forums3/threads/ignition-timing-on-2-st…

Math 050 diam of flywhwl at mark x pi x 360 degrees difference in timing You will probably come out at around two degrees which I think would be barely noticeable When playing with timing it s a good idea to use at least part race fuel

https://garage.grumpysperformance.com//pri…

MRG 988G Crankshaft Key Type Short Crankshaft Key Length in 0 750 in Crankshaft Key Offset 4 degree Crankshaft Key Material Steel Crankshaft Key Color Copper Quantity Sold individually Crankshaft Key Short 4 Degree Offset Chevy Ford Pontiac Mopar Each these come in different designs but youll want ones

http://www.3wheelerworld.com/showthread.php/428…

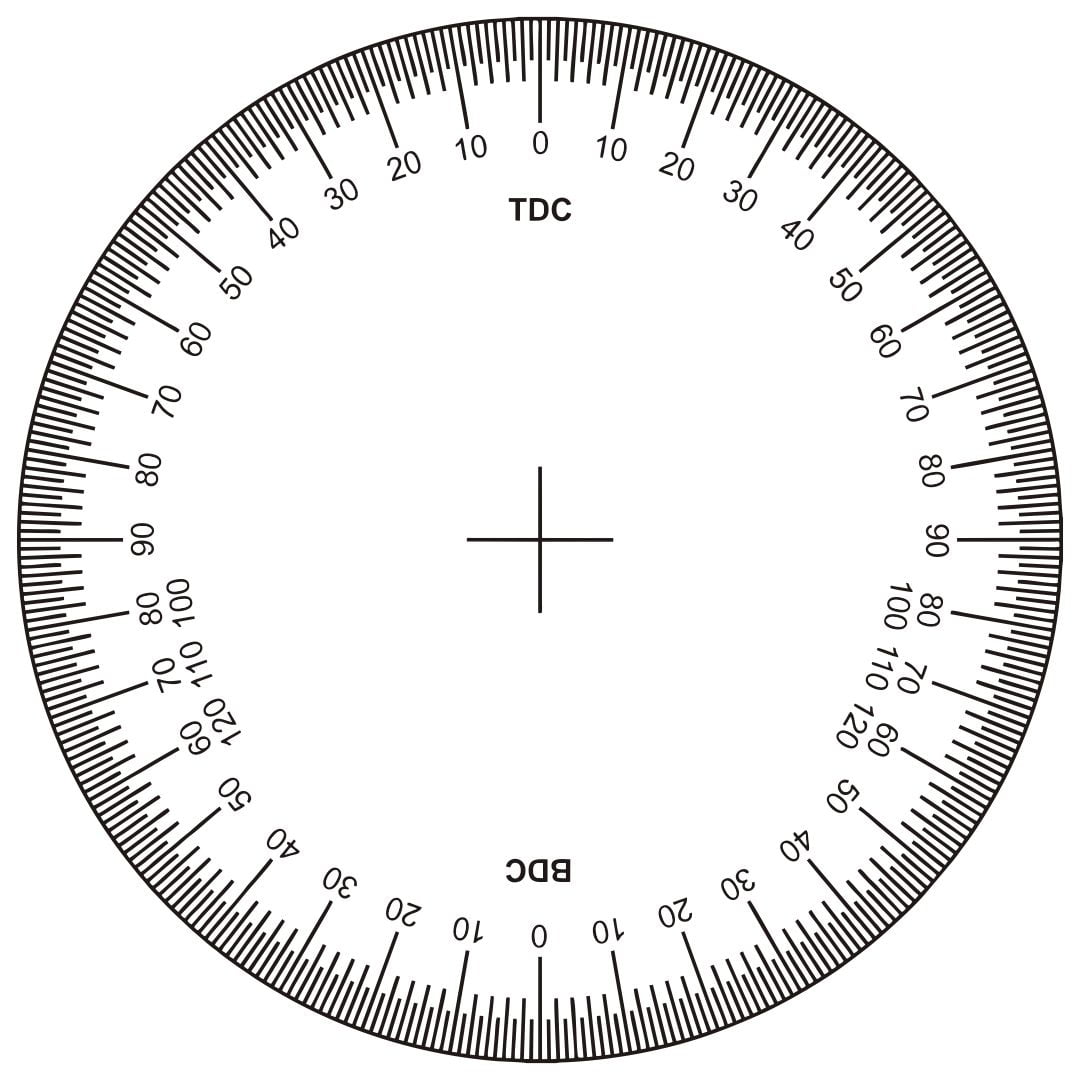

Zero the degree wheel when the piston is at top dead center then rotate the engine untill the f mark comes up Then mark that spot on the degree wheel also marking the piston position Then do the same with the 250 flywheel

https://japan.webike.net/moto_news/webike-original/how-to/…

The timing light timing strobe is used to check the ignition timing in real time for both 2 stroke and 4 stroke engines The same applies to points non contact CDI ignition and transistor ignition There are two types of timing lights battery powered and dry cell powered

Ignition timing is normally in advance of TDC in gas engines because gas burns in a wave like pattern spreading outward from the spark plug The idea of course is to put the optimum pressure on the piston as it drives the crank through it s most mechanically advantageous zone of rotation which starts at around 15 degrees after TDC This is so named for the plotted graph that shows the ignition advance relative to engine rpm If say a theoretical engine needs only 12 degrees of initial advance at idle but perhaps 36 degrees at redline there needs to be a way to advance the spark timing smoothly up and down the rev range

Jan 27 2000 6 961 45 Jan 13 2004 2 Originally posted by Jeff Gilbert I see in the book that timing should be set to 16 5 btdc but how exactly is this measurement accomplished Jeff It depends on if it is 16 5 mm or 16 5 degrees btdc